Additional Features

- SubSea models for use submerged under water

- Brake is enclosed in a gasket sealed area along with bolted-in stainless dual springs and pawls

- Meets IMCA D028 standard (UK sub-sea lever hoist standard)

- Extensive coatings, finishes and materials to resist corrosion

- Fitted with an adjustable chain stop to meet local codes for use under water

X5 Features

- Brake sets and operates without minimum preload

- 100% inspection of hooks per ASME B30 and easy hook replacement is permitted by bolted hook blocks

- All steel body for durable strength in a smaller size

- Powder coat and plated external l parts to resist corrosion

- Caged roller bearings on chain wheels for highest efficiency

- Laser etched stainless steel nameplates with required OSHA /ASME B30 warnings, model and stamped serial number

- Long life fused brake friction disc cannot crack, shatter or absorb moisture

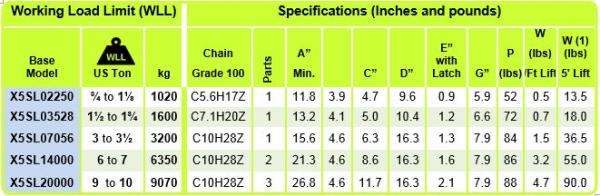

- Grade 100 zinc plated load chain made in Japan or EU

- Ambient Temperature range: -40° to +140°F (-40° to +60°C)

- Meets: OSHA, ASME B30.21 and ASME HST-3. In addition the ultimate strength is 5 times Work Load Limit (WLL) meeting structural requirements of ASME HST-3 Appendix A, for use in marine and other applications as specified by US Department of Defense DOD.

- APEX rating: II 3GD c IIB 60ºC X for limited use in Hazardous Environments

- Final assembly and load test in the USA from imported components. Supplied with certificate by serial

- Open chain guard allows visual inspection and does not trap contamination